The smart Trick of Plant Conveyors And Systems That Nobody is Discussing

Table of ContentsThe Single Strategy To Use For Plant Conveyors And SystemsHow Plant Conveyors And Systems can Save You Time, Stress, and Money.Little Known Questions About Plant Conveyors And Systems.10 Easy Facts About Plant Conveyors And Systems ExplainedPlant Conveyors And Systems - QuestionsThe Best Strategy To Use For Plant Conveyors And SystemsPlant Conveyors And Systems - TruthsThe Main Principles Of Plant Conveyors And Systems

Issues with belt monitoring can be caused by abuse of the conveyor, its environment, and also inadequate upkeep. Pneumatic Pressure Many communicating systems have pneumatically-driven components.

555(a)( 3 ): Emergency stop buttons protect against reactivation of the system up until the emergency situation button is reset to "ON". 555(a)( 4 ): Protective coverings as well as security on screw conveyors are needed. 555(a)( 5 ): Expenses conveyors must have protective coverings below the conveyor.

Rumored Buzz on Plant Conveyors And Systems

0-2020, which covers the risk-free use of machinery and consists of numerous safety and security gadgets that must be component of the installment and also building process. ASME B20. 1-2018: ASME B20. 1 -2018 includes the demands for the style, building, upkeep, and also operation of a conveying system concerning hazards. It is a collection of basic safety and security guidelines.

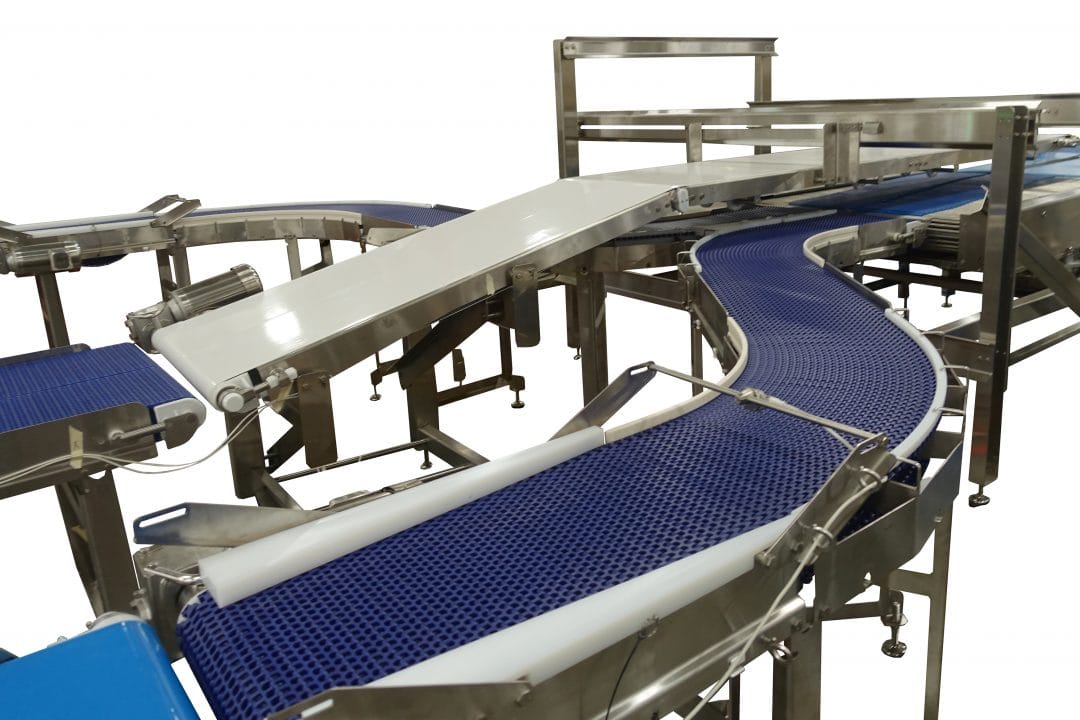

Industrial conveyor systems can be located nearly anywhere virtually all production as well as processing markets require a secure, trusted, automatic way of moving products or items from one location to another within the exact same production facility. It matters not if the item concerned is ground coffee or an automobile chassis product managing systems are an important part of production (Plant Conveyors and Systems).

These will identify what kind of communicating is ideal suited for your production procedures. Each conveyor features its own set of benefits and drawbacks that you should meticulously think about prior to making the decision. Below are seven basic kinds of commercial conveyors and also what you can expect from them.

The Of Plant Conveyors And Systems

At the very same time, if product honesty is not of significance (such as in moving waste), augers have couple of moving components and also are simple to preserve and tidy. The foundation of an aero-mechanical system is the generation of a centrifugal force. This sort of conveyor includes a tube (usually constructed from steel) with an inside distributing rope.

Arguably one of the most typical type of conveyors, belt conveyor systems, have actually found their rightful place in almost every market. This system features pulley-blocks (two or even more) as well as a closed-loop (the conveyor belt) that rotates around them. Several pulley-blocks in the system can be powered, moving the belt in the ideal direction.

You can see them at airports, transporting travel luggage, at restaurants, transporting food (particularly sushi dining establishments), at ski centers, transporting individuals and their ski tools, as well as more. A belt conveyor can be confined to avoid contamination and loss of material, yet also be open if it becomes part of assembly lines - Plant Conveyors and Systems.

The Plant Conveyors And Systems Ideas

As their name recommends, chain conveyors make use of an endless chain to carry product down a manufacturing line. The chain runs over gears at each end of the line, and also it can have special attachments. The most typical application for chain conveyors is the motion of hefty lots bulky materials that are extremely large or really long (or both), such as industrial containers, grid boxes, and also pallets.

Cable conveyors can relocate product in any instructions you require vertically, flat, at angles, and around edges. They have reduced power costs due to the fact that they run on electric motors of 7. 5HP or less. These systems are also fairly simple to preserve due to the fact that they have detachable conveyor elements. The core feature of tubular wire conveyors is that they are extremely gentle on the products.

Take into consideration the dimension and also elevation of the system contrasted to the flooring space of your facility, as well as the kind of product you wish to be communicated. Is it a fragile, powdered product? Loosened material? What is its wetness material? Are you transporting heavy loads as well as big products? Maintenance as well as cleansing expenses, along with feasible downtime for each, need to be taken into consideration.

Plant Conveyors And Systems Can Be Fun For Anyone

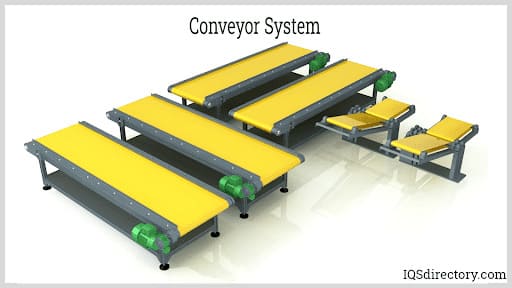

Conveyor Equipments are mechanical gadgets or settings up that carry product with very little initiative. While there are numerous various kinds of conveyor systems, they generally contain a structure that supports either rollers, look what i found wheels, or a belt, whereupon products move from one location to another. They may be powered by an electric motor, by gravity, or by hand.

The conveyor belting is sustained by either a metal slider frying pan for light tons where no rubbing would be put on the belt to cause drag or on rollers. Power is given by electric motors that utilize either variable or consistent speed reduction equipments. The belts themselves can be made from various products, which should represent the problems under which the belt will certainly be running.

Carrying a much heavier tons implies a thicker and more powerful building of conveyor belting product is needed. Belt conveyors are typically powered as well as can be run at different rates depending on the throughput needed.

Little Known Questions About Plant Conveyors And Systems.

Secret specifications consist of the roller size and also axle facility dimensions. The rollers are not powered and also utilize gravity, if inclined, to move the product, or manually if mounted flat.

Cord conveyors can move material in any direction you require up and down, flat, at angles, as well as around corners. They have reduced energy costs due to the fact that dig this they operate on motors of 7. 5HP or much less. These systems are also relatively very easy to preserve because they have removable conveyor elements. The core attribute of tubular cable conveyors is that they are unbelievably gentle on the materials.

Take into consideration the dimension and height of the system compared to the flooring room of your center, as well as the kind of material you want to be communicated. Is it a fragile, powdered product? Loosened product? What is its dampness web content? Are you carrying hefty lots and also huge items? Maintenance as well as cleaning expenses, along with feasible downtime for each and every, should be thought about.

The 7-Minute Rule for Plant Conveyors And Systems

The conveyor belting is sustained by either a metal slider pan for light lots where no rubbing would certainly be related to the belt to trigger drag or on rollers. Power is offered by motors that use either variable or consistent rate reduction gears. The belts themselves can be made from various materials, which need to match to the conditions under which the belt will be running.

Transferring a much heavier load means a thicker and stronger construction of conveyor belting material is called for. Belt conveyors are typically powered and also can be operated at numerous rates depending on the throughput needed. The conveyors can be operated horizontally or can be inclined also. Belt conveyors can be troughed for bulk or large products.

Plant Conveyors And Systems Fundamentals Explained

Secret requirements consist of the roller size and also axle facility measurements. Roller conveyors are used mainly in material handling applications such as on filling docks, for luggage handling, or on setting up lines amongst numerous others. The rollers our website are not powered and use gravity, if inclined, to relocate the item, or manually if installed flat.